PlaneGard™

PlaneGard™ is a fire containment case that is designed to protect people and property from Lithium-ion battery fires that can occur in Portable Electronic Devices (PED’s) such as laptop computers, tablets, readers, smart and cellular phones, digital cameras, and MP3 players. A fire on an airplane, office building or cruise ship is a dangerous situation since there is virtually nowhere to run or hide and separate people from the event. The flames and toxic organic vapors can become overwhelming in a matter of seconds – especially in the confined spaces of an aircraft.

We all know that Lithium-ion (Li-ion) batteries are extremely powerful and do a great job of powering our portable world. What many of us do not know is that they can be extremely dangerous. Each year a growing number of commercial airliners and private aircraft have to be diverted and make emergency landings because of burning Li-ion batteries due to the increasing number of PED’s being carried onboard by passengers and most airlines are installing charging stations in many seats on aircraft. Each year laptops and cellphones are also responsible for dozens of house fires, related damage and even death. The fact is that Li-ion batteries can spontaneously generate heat through a process called “thermal runaway”, and can even cause a fire/explosion when the laptop or cellphone is powered off! With PlaneGard™ on board, this type of emergency can be safely and quickly handled. PlaneGard™ can be used on an airplane to capture, contain and control the heat, flames, toxic organic vapors, smoke, odor and passenger panic associated with these fires. There is no longer a need to make an emergency landing saving the operator considerable expense. Please see the videos below and our PlaneGard™ website (planegard.com) for more details.

Go Battery™

Since the introduction of the first HEV’s (Hybrid Electric Vehicles) more than 10 years ago, HEV technology has floundered in terms of cost-effectiveness. A lower-cost battery system is clearly needed if HEV’s are ever to proliferate and offer the world their true advantage in terms of reducing the dependency on fossil fuels. From a current cost perspective, the Nickel Metal Hydride (NiMH) battery in a Toyota Prius is priced at nearly $3,500 (down from $4,500), while the Lithium-ion (Li-ion) battery in a Chevy Volt is reported as costing $21,000. Plus, these systems require a complicated and expensive Battery Management System (BMS) to operate properly. We therefore argue that HEV’s based on these high-priced battery systems are not really sustainable. The initial cost of the vehicle is too high and the cost of a used car will be tainted and inflated by the fact that the battery will need to be replaced at or near 10 years. This simple fact may severely hamper the used car market.

The HEV industry could also benefit from the use a “greener” battery, one that can truly be recycled and put back into the battery manufacturing process. NiMH batteries are recycled but there is still come debate whether it can be done cost effectively. Li-ion batteries too are purported as being recycled but the industry admits that it is far from cost-effective and only the metal from the can is able to be smelted back into basic materials. The internal workings of the Li-ion battery (current collectors, metal oxides, carbon and polymers are known to be shredded and land-filled. Based on the aforementioned rationale for reduced cost and improved recyclability, there is a clear need for an improved HEV battery. The GO Battery™ is designed to address these issues and more. Based on technology that has exemplary recyclability track record (5-year annual recycling average of 98% - see Battery Council International) and a proven cost that is only a fraction of Ni-MH or Li-ion batteries, The GO Battery TM makes use of advanced VRLA (valve-regulated lead-acid) technology.

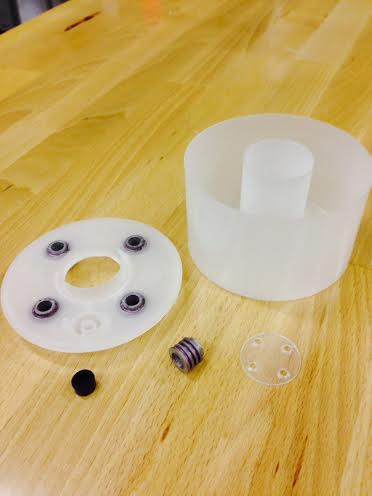

VRLA battery technology is generally also known for power and low temperature performance. The GO Battery™ technology takes this to another level in terms of even higher power, long life and battery pack design options. The GO Battery™ as being developed by HighWater Innovations is a patented design which features a “low aspect ratio spiral-wound cell” (LAR-VRLA) design such as that shown below (See images #1, 2 & 3).

2.

1.

3.

The GO Battery™ cell shown above (1, 2 & 3) has a multi-tabbed low profile grid and dual post construction for extremely high power performance in partial state of charge cycling. The open core and cylindrical shape has been optimized for air-based thermal management and cell to cell stacking / connectivity. This single cell building block can be used to assemble high voltage battery packs of any voltage and offers a wide range of form and fitment to the vehicle designer. The cells shown below (image 4) delivers approximately 6.0 Ah at the 1-hour discharge rate (similar to the cells used for the Toyota Prius) and to have 10-second discharge and charge currents in excess of 400 amps.

4.

5.

Cell resistance is typically 0.9 milli-ohms with short circuit currents in excess of 1,000 amps. Dimensions of this cell as shown (images 4 & 5) are OD = 3”, ID = 1”, Body Height = 1.5” with a cell weight of less than 1.0 pound. Cell performance in the 10-sec power pulse test has exceeded 950W/Kg in these prototype designs.

The prototypes shown (left) are only designed for testing as single cells. The heavy, thick-walled machined ABS containers / covers, along with the bolts and nuts are for prototyping purposes only. These features are practical for individual cell testing as shown below (image 5).

7.

6.

The GO Battery™ cells will ultimately be adapted to stack and interlock thus forming a compact, air-cooled battery pack. This will involve using of a light-weight, thin-wall injection molded container / cover design as shown below (images 6-9). These cells feature a heat-sealed cover that has a raised flange on the central core. The flange is designed to snugly fit into the bottom core of the adjoining cell when stacked end-to-end thus forming a central tube or channel for air-based thermal management.

A 3-cell GO Battery™ pack is shown below (images 8 & 9) for demonstration purposes. Note how the cells will fit neatly together with dual cell interconnecting terminals.

9.

8.

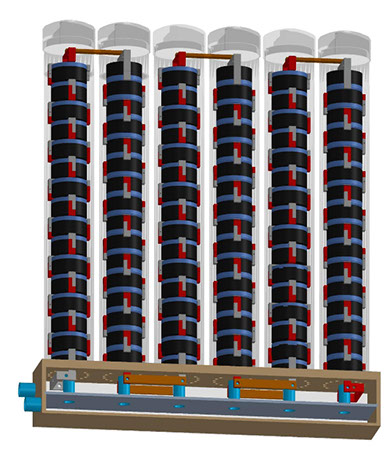

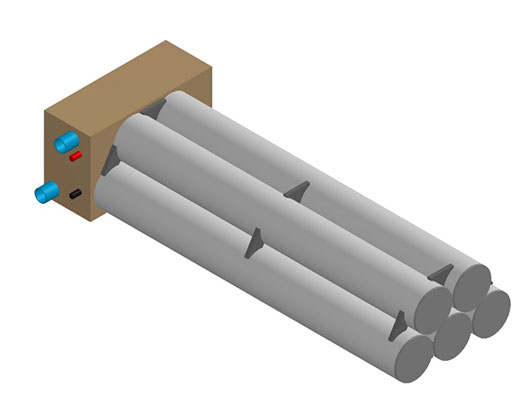

The ultimate design will make use of stacks of 10-20 cells in series arrangement. These “battery stacks” will then be mounted inside thermal management pipes as depicted below. The end cells in each stack will be thermally insulated so that all cells will be thermally matched and will therefore operate at the same temperature. The TM pipes will be mounted side-by-side in an air-management manifold as shown below. The manifold can be linear as indicated (in image 10) or of a trapezoidal design as we demonstrate (in image 11).

10.

11.

The unique design of the The GO Battery™ is estimated to produce more power and have an extended operating life compared to other VRLA batteries. Its low aspect ratio grids will increase the overall power capabilities in the HEV application. The GO Battery™ with it’s open central core, is designed specifically for improved thermal management. Conventional VRLA batteries are known to operate at temperatures of 40 - 45ºC when operated in the High-Rate Partial State of Charge (HRPSOC) cycle. This high operating temperature shortens battery life so it is therefore anticipated that battery life can be increased by 2X through a 10ºC decrease in operating pack temperature using this open core design developed by HighWater Innovations.

As an “advanced battery system”, the The GO Battery™ will be versatile and offer fitment and voltage variations for a wide variety of applications. The innovative design allows the battery to be stacked, with simple connections and therefore facilitate a very compact battery pack to be assembled. This VRLA cell is designed specifically for high power battery packs to be used in hybrid electric vehicles.

Though we are still in the process of building prototype cells, we can offer a battery pack comparison for those interested parties. For example, the NiMH battery pack in the Toyota Prius is has 1.3Kwh of stored energy (pack voltage = 200volts, pack capacity = 6.5Ah). This pack weighs 64 pounds and reportedly sells for ~$4,500. We estimate that a similar The GO Battery™ pack will weigh ~95 pounds and will cost less than 25% the cost of NiMH technology. Complete pack pricing for our design has not been determined – though it will be significantly lower than either competing system, we can tell you that the entire pack will contain less than $200 of lead at current lead pricing!

COPYRIGHT © 2015 Highwater Innovations